Need help? Call us:(+968) 92008595 or info@saiftools.com

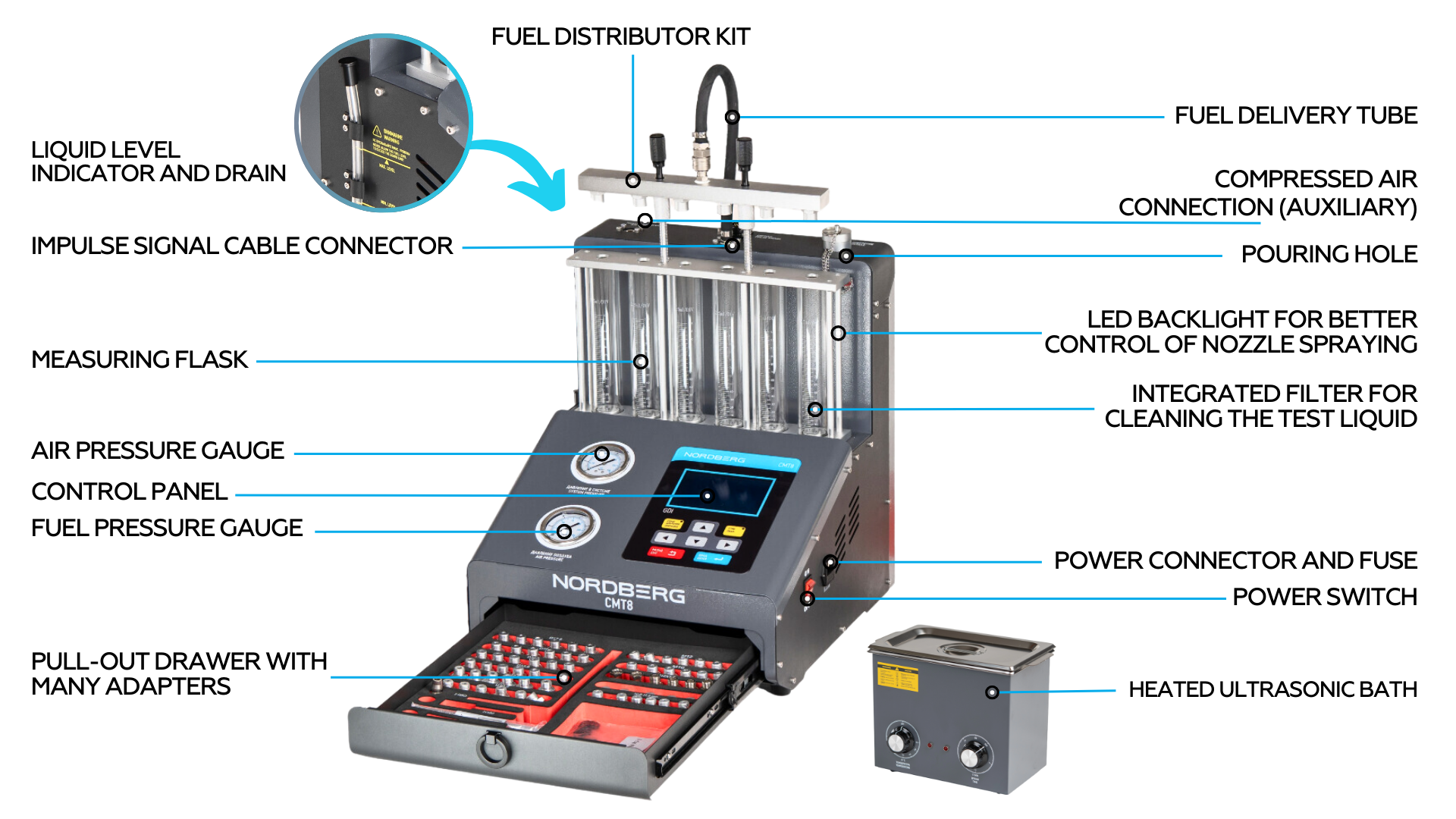

GDI Fuel injector cleaner machine CMT8

| Dimensions | 410 × 440 × 460 mm |

|---|---|

| Brand | Nordberg |

| Main unit power source | ~ 220 V / 3 A |

| Ultrasound cleaner power source | ~220 V / 2.5 A |

| Main unit power | 350 W |

| Ultrasound cleaner power | 120 W |

| Ultrasound cleaner heater power | 100 W |

| Operating pressure | 4-8 bar |

| Range of simulated speeds | 100-9900 rpm; step: 100 rpm |

| Pulse width | 0.1-30 ms; step 0.1 ms |

| Time range | 60-3600 s |

| Ultrasound cleaning timer | on, 5-20 minutes |

| Ultrasound cleaner heating temperature | 20-80 °C |

| Fuel tank capacity | 3.7 L |

Description

Fuel injector cleaner machine NORDBERG CMT8

The GDI CMT8 injector testing and cleaning unit is designed for diagnosing, testing, and cleaning GDI (Gasoline Direct Injection) injectors and other types of injectors used in gasoline direct injection systems into engine cylinders. The unit is used in auto repair shops for servicing and repairing vehicles with GDI engines.

This product is not a household appliance and is considered specialized professional equipment intended for use in technical service stations or other industrial premises. The product should be operated by individuals with the necessary professional training.

Functional features

- The product operates by simulating engine operating conditions. The unit allows for identifying faults and performance of EFI and GDI injectors, as well as cleaning them to restore normal engine operation, improve engine performance, reduce fuel consumption, and extend injector service life. This product provides only the basic configuration, additional connector sets must be purchased separately.

- In addition to cleaning fuel injectors, the ultrasonic device can also clean the fuel pump, spark plug, and other small parts, but pay attention to the choice appropriate cleaning agent.

Functions

- Spray torch test (test for uniformity of sprayability) – to check the uniformity of the amount

- Ultrasonic cleaning – for simultaneous cleaning of nozzles with removal of carbon deposits. of injected liquid and control of the spraying condition of each nozzle. Presence of backlighting. This test is also designed for reverse flushing.

- Tightness check (leak test) to check the sealing and dripping conditions of the injector nozzles under pressure in the system.

- Performance test to check the injection volume of the nozzle for 15 seconds of constant injection.

- Automatic test – to check the nozzles by simulating various operating conditions

- Auto cleaning (car cleaning function)

Distinctive Features

Compact and easy to use, the product allows for technical maintenance of injectors with removal on and off the vehicle, ensuring engine reliability and trouble-free operation with minimal time and effort.

- Using powerful ultrasonic cleaning technology, the product ensures complete cleaning of nozzles.

- Fuel pressure control through a microcomputer provides stable pressure control and a wide adjustable range suitable for all GDI system vehicles and can help provide automatic cleaning and checking of nozzles.

- With microcomputer control and digital display, the equipment provides automatic operation of the product and monitoring of dynamic values in real-time mode.

- Automatic fuel drain according to preset programs for certain test modes. Test fluid/detergent can also be drained by pressing a button on the control panel after the test.

- A human-oriented approach to product design takes into account human factors such as ease of use, ergonomics, interface clarity, etc., ensuring more efficient and enjoyable use of the product.

- LCD display for showing operation details.

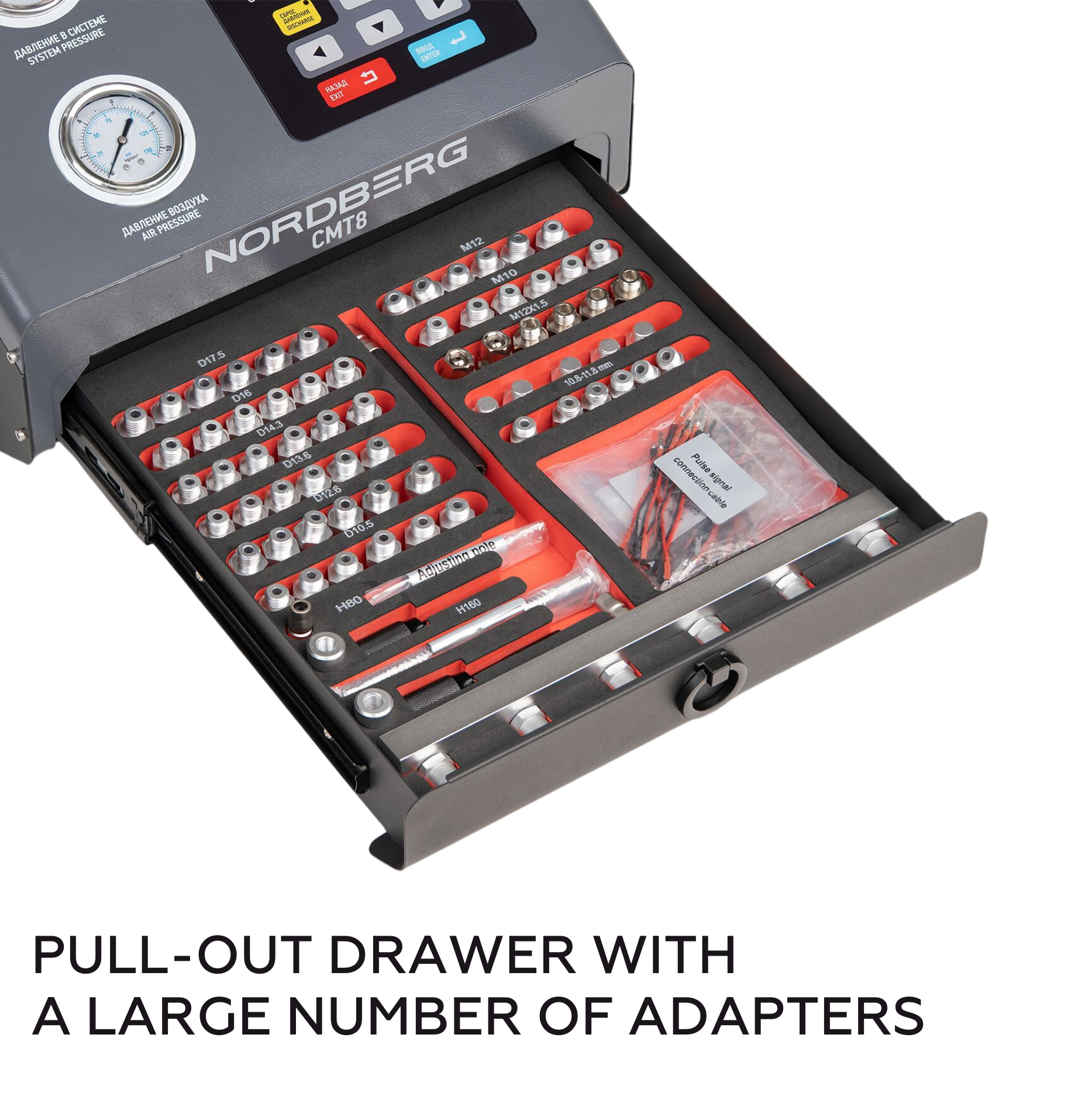

Contents

- Injector testing and cleaning setup GDI

- Ultrasonic cleaner (including cover, cleaning bracket)

- Fuel distributor kit, including adapter 2 (D13.5)

- 6-cylinder pulse cables

- Pulse signal connector cable 1 (6 pcs)

- Pulse signal connector cable 2 (6 pcs)

- Pulse signal connector cable 3 (6 pcs)

- Adapter 1 for top feed injector (D10.5) (6 pcs)

- Adapter with Swiss thread for top feed injector (M10x1.0) (6 pcs)

- Adapter with large thread for top feed injector (M12x1.75) (6 pcs)

- Plug (G1/4″) (5 pcs)

- Knurled nut (2 pcs)

- Adjustment stand (H80) (2 pcs)

- Adjustment stand 2 (H160) (2 pcs)

- Pressure screw (2 pcs)

- Adapter for upper fuel injector delivery (D10.8-11.8) (6 pcs)

- Adapter for upper fuel injector delivery fuel delivery (D12.6) (6 pcs)

- Adapter for BENZ GDI injector (D16) (6 pcs)

- Adapter for universal injector delivery of fuel (D17.5) (6 pcs)

- Adapter for upper fuel injector delivery (D16) (6 pcs)

- GDI injector adapter (M12X1.75) (6 pcs)

- Adapter for upper fuel injector delivery fuel delivery (D14.3) (6 pcs)

- Adapter for upper fuel injector delivery

fuel delivery (D13.6) (6 pcs) - Set of sealing rings

- Test adapter

- Air intake adapter

- Case

- Funnel

- Power cable (2 pcs)

Related products

Al Saif Business And Investment SPC

Need Help?

Store Information

Customer Service

Copyright 2025 ©. All right reserved. Designed by Reluctech Media.

Reviews

There are no reviews yet.